The Impact of Mucilage Removers on Coffee Sustainability and Quality - 25 Magazine: Issue 6

Over the course of the three quarters of a century they’ve been available, the role of the mucilage remover has shifted and changed as different coffee waves went by, the demand for specialty coffee increased, and sustainability became a key focus of the industry.

CARLOS HENRIQUE JORGE BRANDO[i] traces the design changes that have brought water-saving demucilagers to the fore of a conversation about sustainability and coffee quality.

As the name suggests, a “mucilage remover” is a machine that removes mucilage attached to parchment coffee either by itself, or in conjunction with fermentation. Generally, mechanical removal of the mucilage is achieved by friction between parchment beans themselves and the parts of the machines (rotor and screens).

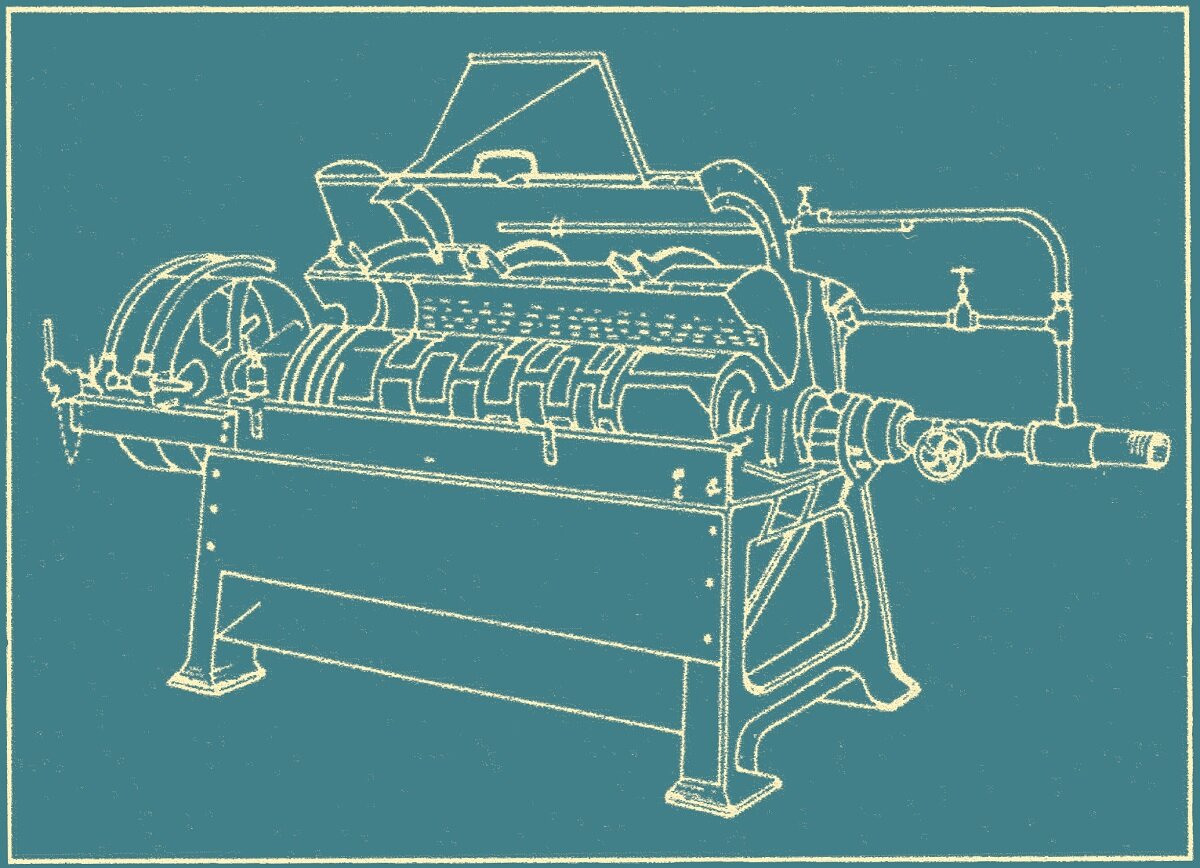

The Aquapulpa, the first machine of its kind, was developed as both a pulper and mucilage remover for Robusta coffee. From: R. Wilbaux.

The first such machine, the aquapulpa, was originally developed as both a pulper and a mucilage remover for Robusta coffee. Later, it was empirically found to also work as a mucilage remover alone, for both Arabica and Robusta coffee. Although efficient, it became known for huge water consumption – over 4 m3 of water per ton of wet parchment[ii] – and high power requirement (up to 10 hp per ton of wet parchment). The aquapulpa consists of a horizontal rotating drum assembled inside a fixed screen cylinder. The inner drum has screw-shaped channels on the feed side, to force the cherries to move forward, with cleats further on, parallel and at right angles to the coffee flow. A gate with a counterweight is fitted at the outlet of the screen cylinder.

It was only 40 years later, in the 1980s, that a new, albeit short-lived, technology arrived. Its downward vertical flow and increased friction of coffee beans against each other, rather than against the parts of the machine, helped to save power and water (another generation of machines would arrive only 10 years later, better on both counts). Where the aquapulpa had a horizontal drum, the new ELMU mucilage remover had a vertical shaft, with metallic fingers placed at right angles and pointing out radially. The shaft and fingers revolved inside a vertical jacket with another set of similar fingers pointing to its center, located between the other fingers.

Mucilage remover ELMU with washing conveyor. From: CIRAD-CP.

Drained parchment is fed into the top of the machine, with mucilage removed through the friction of the coffee against itself as well as the fixed and mobile fingers as parchment moves downwards by gravity. A counterweight is located at the outlet at the bottom of the machine to regulate the degree of washing; water is injected in the upper and lower thirds of the cylinder to facilitate washing and to help parchment flow out of the machine. As the ELMU discharges parchment mixed with mucilage, a washing device like a screw conveyor had to be installed after the machine.

The downward vertical flow of the ELMU substantially decreased water consumption and power requirement – 3 to 5 hp per ton of pulped coffee, down from the 10 hp of the aquapulpa – and also lowered physical damage to parchment and beans.

Upward flow mucilage remover. From: CIRAD-CP according to Penagos.

First developed in the early 1990s, the most recent addition to the family of mucilage removers uses upward flow (compared to the downward flow of the ELMU) to further increase friction of the parchment against itself and the machine parts. This change in directional flow brought water consumption and power requirement further down. These are the machines still offered today by several companies with different configurations and constant redevelopment ever seeking to decrease water and power usage and physical damage to coffee.

This upward vertical flow machine consists of an endless screw in its lower section and a set of agitators – cogwheel teeth, pins, small fingers, or beaters, depending on the model and maker – in its upper section. The rotor is assembled inside a cylindrical screen cage made of a perforated steel plate or welded wire. The screen cage and the rotor are set in a case that retains water and mucilage and directs their flow downwards; drained pulped coffee is fed into the base of the machine.

The endless screw moves parchment up to the section with agitators, where mucilage is removed through the friction of both the parchment against itself as well as the rotor and the screen. Mucilage flows through the holes of the screen in the form of a very viscous liquid, discharged at the bottom of the machine. Parchment without mucilage – and without the need for further washing, as with the ELMU – exits at the top of the machine. This new generation of machines decreased water consumption even further to 0.5 to 1 m3 of water per ton of wet parchment[iii], a reduced power requirement of 1.5 to 3 hp per ton of pulped coffee, and brought physical damage to a minimum.

The use of mucilage removers gained importance as both water consumption and power requirement progressively fell by 70–80% and as the need to decrease water consumption and contamination arose in response to sustainability demands of the second wave. Wet fermentation is undoubtedly the major source of water consumption and contamination in wet milling, to say nothing of the labor requirement. Mechanical removal of mucilage drastically decreases water consumption, facilitates its treatment, reduces the labor requirement, and enables better control of the process. Additionally, mechanical demucilaging serves an important function: cutting down weight loss of coffee during processing. Sivetz and Desrosier state in their book Coffee Technology that, due to normal metabolism and respiration during fermentation, coffee may lose weight: seldom less than 0.5% and often much higher than this, reaching even 6 or 9% in extreme cases of very long fermentation and high weather temperatures. When combined, the advantages of mucilage removers were so many that, at a point in time, it seemed that they were in fact going to replace fermentation in wet milling.

The debate about the quality of the final product coming out of the two systems was never really settled, with two important perceptions arising. First, fermentation should be retained only where it improved cup acidity, i.e. at higher altitudes. Second, even in these cases, it could be shortened without quality losses if a mucilage remover was used at the end of the process to allow better control, as well as to decrease water and labor requirement and weight loss. First wave coffee could probably rely on mechanical demucilaging alone, whereas second wave was more sensitive to the impacts of fermentation, opting sometimes for a combined approach of fermentation and mechanical removal. The best growers’ response to new market trends was then to rely on both systems and to be prepared to process in different ways for different clients.

Third wave coffee drove quality requirements even higher, with stronger reliance on fermentation. But wet fermentation started to be questioned: given our sustainability concerns, is it the most sustainable option?

Dry fermentation had always existed – used in only a few origins for several reasons, from control difficulties to the need to use water to wash coffee at the end of fermentation any way – but this brought renewed attention. The ability to use “vertical” silos instead of “horizontal” tanks for dry fermentation in order to facilitate the handling of the product without water, the dry feeding of parchment into mucilage removers to wash out the remaining mucilage and complete the process, allows for maximized quality to sit alongside minimum water and labor usage. The two tenants of sustainability and quality have brought mucilage removers to play a major role in the processing of coffee, bringing it to new levels of quality, efficiency, and sustainability at all altitudes coffee is grown.

Last but not least, mucilage removers may play an important role in the production of recently popular pulped natural/honey coffees. Originally conceived in Brazil as parchment dried with all mucilage attached, pulped natural coffee was then also produced with only some mucilage (not all) attached to parchment in order to facilitate drying – primarily because it sticks less to tools and driers. The desire to be able to produce these coffees requires the removal of some mucilage, leading to further interest in and use of mucilage removers. Red and yellow honey coffees, a pulped natural dried with less than all the mucilage attached to parchment, requires the use of good quality, adjustable mucilage removers. Pulped natural coffee that dries with all mucilage attached to parchment, also known as black honey, does not obviously require mucilage removers.

The quest to improve continues with makers trying to further decrease water consumption while improving coffee quality. This development process is mostly situated around the upward flow mucilage remover that is today considered the state-of-the-art equipment to perform this task. As the role of mucilage removers has changed over the years – and the focus of continued improvement has shifted from quality to sustainability and back – the producers of demucilagers have continued to iterate on its design in order to meet customer needs.

Today, dry fermentation with dry mechanical feeding of mucilage removers is thought to get the best quality with the least environmental impact. Slowly but steadily, mucilage removers have carved their way into the wet processing of coffees of all qualities, with positive impacts on quality, sustainability, and cost-benefit.

CARLOS HENRIQUE JORGE BRANDO, a former SPURS Fellow at MIT, is a Director and Partner at P&A International Marketing; Chairman of the Board of the Global Coffee Platform (GCP); current member of the Coffee Quality Institute Board of Trustees and the Coffee Chamber of [B]³ (former M&FBovespa); and a founder of both the Museu do Café (Santos) and the African Fine Coffees Association (AFCA), who honored him with a Lifetime Achievement Award in 2017.

References

[i] Substantial parts of this piece are based on, updated, or extracted from the author’s chapter, “Harvesting and Green Coffee Processing,” found in Coffee: Growing, Processing, Sustainable Production, edited by Jean Wintgens.

[ii] This is equivalent to 4,000 L of water per 430 kg of green coffee or 360 kg of roasted coffee or 9.3 L of water per 1 kg of green coffee / 11.1 L of water per 1 kg of roasted coffee.

[iii] This is equivalent to 500–1,000 L per 430 kg of green or 360 kg of roasted coffee or 1.2–2.4 L per 1 kg of green coffee / 1.4–2.8 L per 1 kg of roasted coffee.